Asiga for digital dentistry

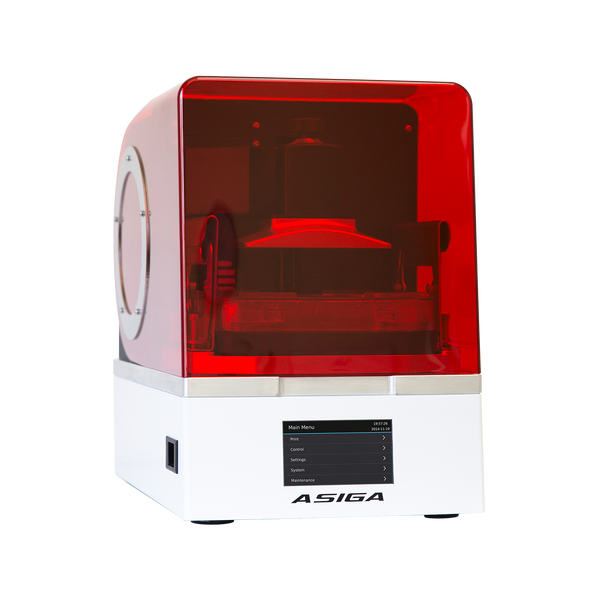

Asiga MAX UV

Asiga printers are well-known for their high accuracy due to their process monitoring technologies which ensure that every layer is formed accurately. All printers have an open material system and therefore offer complete freedom of choice when it comes to resin.

In addition, the MAX UV offers extraordinary productivity in a very small footprint. Offering 62µm HD print precision, this printer is ideal for dental lab production. What’s more, the Asiga MAX UV is trusted by laboratories worldwide to perform in the most challenging of production environments.

What's Included

Taking the dental industry by storm, from day one to now. The Max’s 62µm pixel resolution is optimized for dental environments, where precision is paramount. As an open materials system with over 400 resins validated, the Max is ready to manufacture dental orthodontics, crown & bridge, surgical guides, dental models, custom trays and partial dentures. Asiga’s unique SPS™ process guarantees every layer is formed accurately. Accurate layer formation is the key to achieving consistently accurate results in any production environment. The 385 nm light source cures faster at deeper UV wavelengths, reducing XY scattering and over-cure. The result is sharper detail definition, accuracy, production reliability and the ability to process water-clear materials.

- 62µm Print Precision – Optimized for both dental environments.

- Ideal for dental models, surgical guides, denture bases, temporaries, partial frameworks, IBT’s, crown and bridge, custom trays, splints, and more.

- Industry Proven Performance – Precision, reliability and speed for the most demanding production applications.

- Latest DLP Imaging Technology – Coupled with custom engineered optics for precision pixel placement.

- Proprietary Layering Processes – Repeatable precision with Asiga’s proven Process Monitoring Technologies.

- Super Fast Print Mode Available – Volume production in minimal time.

- SPS™ Smart-Positioning-System Technology – Asiga’s unique SPS™ process guarantees every layer is formed accurately resulting in consistent results in any environment.

- Open Material System – Print with any suitable material from any material manufacturer. Your choice, no strings.

- Seamless Integration – Simple touch screen user interface and multiple connection options for seamless integration into your digital workflow.

- Large Print Envelope – For volume throughput with high-speed print options.

Product specification |

|

| Build Volume X, Y, Z | 119 × 67 × 75mm 4.69 × 2.64 × 2.95 inches |

| Pixel Resolution | 62µm |

| Technology | DLP |

| LED Wavelength | 385nm (high power UV LED) or 405nm |

| Material Compatibility | Asiga materials, 100% Open Material System — use any suitable third party material |

| Software | Asiga Composer software. Lifetime updates included |

| File Inputs | STL, SLC, PLY, STM (Asiga Stomp file format) |

| Network Compatibility | Wifi, Wireless Direct, Ethernet |

| Power Requirements | 100 to 240 VAC, 50/60 Hz, ≤2 Amps |

| System Sizing | 260 × 385 × 370mm / 19.3 kg 10.2 × 15.2 × 14.5 inches / 42.6 lb |

| Packed Sizing | 410 × 500 × 480mm / 21.6 kg 16.1 × 19.7 × 18.9 inches / 47.6 lb |

| Warranty | 12 months manufacturer’s warranty |

| Technical Support | Unlimited lifetime technical support included |

| Bundle Includes | 3D printer, Composer software, 1 kg Asiga material, 1L build tray, Asiga Flash post-curing chamber, calibration toolkit |